September 5-6, 2024 | Shanghai, China 2024年9月5-6日,中国上海

We are thrilled to present the 2024 ISTA China Packaging Symposium to be held on September 5-6 at the Wyndham Shanghai Nanxiang in Shanghai, China. The Symposium is hosted by International Safe Transit Association China Division and presented by China Packaging Research & Test Center and China Packaging Research Institute.

我们很高兴地宣布,2024年ISTA中国包装研讨会将于9月5日至6日在中国上海的温德姆上海南翔酒店举行。本次研讨会由国际安全运输协会中国分会主办,由中国包装科研测试中心和中国包装研究院联合承办。点击这里查看 ISTA 中国网站。

Register in English (US Dollars)

Schedule 时间表

WEDNESDAY 09/04/2024

- 14:00-20:00 Check-in and Registration; Location: Wyndham Shanghai Nanxiang

- 9:00-17:00 2024 ISTA China Transport Packaging Design Competition Finals; Location: M49 Meeting Room, N5 Hall, Shanghai New International Expo Center

- 13:30-17:00 “Logistics Supply Chain Cost Reduction and Recycling of Foam Materials for Packaging” Forum; Location: M50 meeting room, N5 Hall, Shanghai New International Expo Center

THURSDAY 09/05/2024

Location: Wyndham Shanghai Nanxiang

- 08:30-09:00 Check-in and Registration

- 09:00-09:30 Opening Ceremony

- 09:30-10:30 Speech

- 10:30-11:00 Tea Break and Business Exchange

- 11:00-12:00 Speech

- 12:00-13:30 Buffet Lunch

- 13:30-15:00 Speech

- 15:00-15:30 Tea Break and Business Exchange

- 15:30-17:00 Speech

- 17:00-18:00 Break and Business Exchange

- 18:00-20:00 2024 5th ISTA China Transport Packaging Design Competition Award Dinner

FRIDAY 09/06/2024

Location: Wyndham Shanghai Nanxiang

- 09:00-10:00 Speech

- 10:00-10:30 Tea Break and Business Exchange

- 10:30-12:00 Speech

- 12:00-13:30 Buffet Lunch

- 13:30-15:00 Speech

- 15:00-15:15 Closing Speech

SATURDAY 09/07/2024

Location: Wyndham Shanghai Nanxiang

- 09:00-12:00 ISTA China Board Meeting

Note: The agenda of the symposium is subject to the final arrangement of the host.

Speakers 扬声器

Palletized Temperature and Humidity Controlled Transportation Solutions

Shuan Hu, Technical Manager, Shanghai Yuan Ting Technology Co., Ltd.

Presentation summary

Products such as special electronic components, specialty chemicals and pharmaceuticals have strict requirements for transportation conditions, including temperature and humidity. Long-distance transportation usually uses active temperature control solutions such as thermostatic warehouse, which is more costly and subject to resource constraints. Passive temperature control does not have the risk of power failure, but requires strict evaluation of the temperature control range; due to the special properties of the transported products, it is strictly required that the phase change material must not be leaked, and at the same time, there are high requirements for the dimensional compatibility of the internal payload size. On the technical platform of our full/hall stack pallet container, this palletized temperature and humidity control transportation solution is created through a series of steps, such as enlargement of the size, customized development of phase change material, changes in the initial physical state of phase change material, and changes in the loading mode of phase change material.

Takeaways:

- Comparison of active and passive temperature controlled transportation solutions; How to realize variable payload size and operation convenience;

- How to control the humidity inside the box;

- How to control the temperature inside the container at 21~25 ℃ and keep it for 4-5 days in international transportation;

- How to achieve the phase change material does not flow and does not leak.

Biography: Packaging Engineering in Shanghai University (Bachelor's Degree), Logistics Management in University of Lincoln (Master's Degree). After graduation, he joined Shanghai Shengsheng Logistics, worked in the operation center, quality center, solutions and training department successively. Now he is the technical manager of Shanghai Yuanting, a wholly-owned subsidiary of Shanghai Shengsheng, he developed several series of pharmaceutical cold chain transportation packaging based on vacuum insulation panel and phase change material, and customized cold chain transportation packaging solutions for other industries. He also possesses the skills of production process, quality system management, and ISTA 7D testing. He has been won the third prize in the China Creative Packaging Design Award, and he has participated in the formulation of the national standard “Determination of effective thermal conductivity for vacuum insulation panels(VIP)”.

Design and Testing Research of Lighting Packaging

Xu Xin, Global Packaging Centre of Excellence - Packaging Technology Manager/Expert, SignifyPresentation summary

Challenges for home lighting products during express and storage:Packaging design principles introduce the selection of materials and design structures based on product characteristics, and how these choices affect the safety of products during transportation. Problems in packaging testing standards and methods (such as the impact of climate/logistics/warehousing/material differences, etc.), explain the purpose and execution of different testing methods, and understand how to verify the effectiveness of packaging design. Through such innovations in packaging design and testing, it is in line with the trend of green and sustainable development of packaging in the future, and these is a very important role in reducing damage and complaints caused by packaging in transportation.

Takeaways:

- Matching Product Characteristics with Packaging;

- Selection of Transportation Conditions and Tests;

- Factors affecting package stability and test verification.

Biography: Xu Xin joined Philips in 1997, as a Packaging Technology Manager/Expert. He is responsible for designing packaging for various products, developing green and sustainable packaging solutions, and conducting product packaging tests and risk assessments. His professional capabilities in the packaging field are highly recognized in the industry. He possesses specialized skills in packaging design and engineering, and has extensive experience in packaging testing standards and audit requirements. Xu also excels in supplier management and warehouse logistics management. Additionally, he has published numerous important papers in professional packaging journals and has received multiple awards for packaging design. He serves as a senior professional judge in various industry activities and delivers keynote speeches at numerous domestic and international packaging forums and summits. Xu also holds positions as an expert/member and director in several national packaging associations and organizations.

Design of temperature control box for unmanned aerial vehicle medical transportation

Zhao Liang, Co-founder, Chief Products Officer, Hangzhou Antwork Technology Co., Ltd.Presentation summary

The development of low altitude economy is accelerating, and drone logistics transportation is the most important low altitude application scenario. The packaging technology of drone transportation is also an important part of it. The unmanned aerial vehicle (UAV) medical transportation dedicated temperature control box is the first "low altitude container" designed for special materials with strict temperature control requirements such as blood during low altitude transportation. As the pioneer of urban air logistics in China, the R&D unit Antwork has now operated more than 200 commercial routes in nearly 30 cities, and has designed and developed it through the service experience of more than 100 medical institutions such as Zhejiang Blood Center and the Second Affiliated Hospital of Zhejiang University, as well as the experience of more than 100000 safe flights, realizing accurate temperature control, easy disinfection and sterilization and traceability throughout the transportation process in multi temperature areas. At the same time, to meet the requirements of lightweight, high safety, and real-time monitoring in low altitude flight, the box also has characteristics such as lightweight, anti fall, and wide area communication.

Takeaways:

- The unmanned aerial vehicle (UAV) medical transportation dedicated temperature control box is the first "low altitude container" designed for special materials with strict temperature control requirements such as blood during low altitude transportation;

- To meet the requirements of lightweight, high safety, and real-time monitoring in low altitude flight, the box also has characteristics such as lightweight, anti fall, and wide area communication.

Biography: Graduated from the Aerospace Design major at Beihang University. Co founder of Antwork, responsible for product design related work in the company. Consultant expert of the UAV Working Group of the Civil Aviation Administration of China; Leader of multiple drone industry standards,

The Exploration Practice of Eco-friendly Visual Transparent Packaging of Home Appliances to Reduce Resource Waste

Yangchao Wang, Senior Quality Engineer of Haier Chongqing Drum Wahing Co,.ltd, Qingdao Haier Washing Machine Co. LTDPresentation summary

Through the application of this project, the domestic transparent packaging application market is opened, and the transparent packaging will play a demonstration role, so as to radiate to other industries and provide a reference path for the green development of the packaging industry. The transparent packaging scheme of Haier washing machine reduces the paper consumption by 90% and the defect rate of appearance damage decreases by 70%. The total switch of transparent packaging in the washing industry is expected to reduce the use of 560,000 tons of base paper every year, that is, reduce the use of 1.74 million m³ wood, equivalent to reducing the felling of 37,500 hectares of trees. Under the influence of Haier's washing industry, the company promoted the introduction of transparent packaging to transparent packaging and air conditioning industries, which is equivalent to reducing deforestation by 162,600 hectares every year and achieving the goal of sustainable development.

Takeaways:

- A new transparent packaging scheme for home appliances, reduce the use of paper, save resources, promote environmental protection, to meet customer needs;

- Implementation method of the project.

Biography: Senior Quality Engineer of Haier Smart Home\ Group owner of DWM transport damage quality improvement . Initiated Haier transport damage improvement three-step method: short-term - focus on transportation scene improvement → medium term - focus on product structure optimization → long-term - focus on transportation standards upgrade. Engaged in drum washing machine transportation damage research for several years, participated in the formulation of packaging testing, packaging materials and other related standards. With packaging research and development, manufacturing, transportation and other goods damage whole value chain quality management experience

Research on Transportation Reliability of Medical Imaging Equipment

Jia Dongfang, Reliability Technical Leader, Shanghai United Imaging Healthcare Co., Ltd.(UIH)Presentation summary

In recent years, with the rapid development of domestic medical imaging equipment and the continuous improvement of the product chain, domestically produced medical imaging equipment has been widely sold not only to various grassroots hospitals in China, but also to various locations around the world. This means that medical imaging equipment is now faced with more complex and challenging transportation scenarios. It is well known that medical imaging equipment itself is valuable, heavy, and delicate, and these complex and challenging transportation scenarios pose great challenges to it. This research utilizes systematic reliability technology and theory to study the realization of the reliability technology of medical imaging equipment and its packaging from the perspective of transportation. Firstly, requirements analysis establishes potential core requirements based on the market, and analyzes the possible environmental profiles and primary failure stresses. Secondly, targeted design or protection measures are taken against the major failure stresses, including the design protection of products and packaging, as well as the improvement of transportation tools. Finally, quantitative verification corresponding to the requirements is established for the packaged products, ultimately realizing a closed loop of reliability from requirements to verification, and reducing the potential losses that may occur during actual transportation of the products.

Takeaways:

- Medical imaging equipment has limited anti-vibration and shock resistance, but the real transportation scenarios require higher standards;

- Transportation reliability requires a closed loop, including requirements analysis, design protection, and testing verification;

- Requirements analysis is often potential and includes environmental profiles and failure stresses;

- Design protection includes the design of products and packaging, as well as the improvement of transportation tools;

- Testing verification needs to be a closed loop with requirements analysis, achieving quantitative verification.

Biography: I graduated from Shanghai University in 2010 with a master's degree, and joined Shanghai United Imaging Healthcare Co., Ltd. (UIH) in 2011. I have been engaged in research and development as well as reliability technology work, and am currently the leader of reliability technology at UIH. I have established a systematic technical system for reliability at UIH, covering the entire life cycle of reliability from storage, transportation, production to use. During this period, successful reliability technology solutions were provided for the vehicular and shipborne adaptation of 9 products including CT, PET-CT, and DR. I also led 7 products including CT, PET-CT, and DR to pass the most critical seismic test OSP seismic certification of California. I have obtained multiple invention and utility model patents, and successfully completed the 13th Five-Year "National Key R&D Program - Digital Medical Equipment R&D Key Special Project" of the Ministry of Science and Technology as a technical backbone. I have also participated in the drafting of 5 industry and group standards, and won the second prize of the "Shanghai Quality Association Quality Technology Award".

Scientific and reasonable selection of logistics returnable packaging

Ryan Huang, Deputy Secretary General/Secretary General of Logistic Packaging Committee, Shanghai Packaging Technology AssociationPresentation summary

Returnable packaging solutions for logistics have considerable advantages in the current dual-carbon and circular economy situation, whether from the use and consumption of raw material resources, or in the total cost per unit; It has great replaceable ability for disposable packaging under specific conditions. Many companies simply think that a set of packaging used 10 times will be equivalent to 1/10 of the cost, in fact, how to choose returnable packaging solutions, is the need to use a scientific attitude to face and plan. This report will rely on the content of the group standard "Evaluation and calculation method of returnable packaging selection", introduce how to make a scientific and reasonable choice between disposable packaging and returnable packaging schemes, and introduce the solution of intelligent recycling packaging.

Takeaways:

- The definition of logistics returnable packaging;

- The whole process of logistics returnable packaging;

- The cost of logistics returnable packaging;

- "Evaluation and Calculation Method of Returnable Packaging Selection" group standard introduction; Case Study.

Biography: Professorate Sn. Engr.(Light industrial product design, manufacturing and intelligent technology application) / Master . Morn than 20 years working experience in transportation packaging industry, good at total packaging solution design, transportation packaging testing and lab management, packaging materials applied research and development. Now mainly engaged in packaging structure design scheme information, packaging technology consulting and training, and association work. Deputy Secretary General of Shanghai Packaging Technology Association & Secretary General of Logistics Packaging Committee, editor-in-chief of Shanghai Packaging magazine; Vice President of ISTA China Regional Education Committee and guest lecturer of Advanced Training Course (APDTC)

Exploring the Sustainability of Transport Packaging and Its Solutions

Birkoff Chen, Global Hardlines Product Manager – Sustainability, SGS-CSTC Standards Technical Service Co.,Ltd.Presentation summary

Explores the contradiction between environmental protection and practicality in plastic packaging, the core concept of the circular economy, the validity of environmental claims, and the application of technology in assessing the performance of recycled materials. 1.

- Environmental Protection vs Practicality: Through the case study of transport packaging, we analyze the dual nature of plastic packaging: Transport packaging broadly adopts plastic materials due to their durability, lightness, and waterproof characteristics, bringing about high practical value. However, the production, use, and waste disposal processes of plastic transport packaging also pose serious environmental problems. We need to explore how plastic transport packaging can achieve better performance in environmental protection while achieving practical functions.

- The core of the circular economy: Starting with transport packaging, explore the feasibility of plastic recycling: The extensive use and waste of transport packaging make it a key object for plastic recycling. By evaluating the recycling content and recyclability of transport packaging, we can clarify its value in resource recycling and improve its recyclability through improved design, thereby promoting the development of a circular economy.

- Authenticity of green claims: Verify the authenticity of environmental claims: Various transport packaging manufacturers are making environmental promises to enhance their brand image. However, whether these environmental promises are true needs to be validated through strict environmental claims verification. The systematic assessment of the lifecycle environmental impact of its products or services by a third party can ensure the truthfulness and credibility of its claims.

- Technology and Environmental Protection: The focus is on identifying the performance of recycled material packaging: Advances in technology provide the possibility for evaluating and improving the recycling of plastic packaging, particularly in identifying the physical, chemical, and mechanical properties of recycled transport packaging materials. This not only helps in evaluating their reuse value, but also improves their treatment process.

Takeaways:

- Environment vs. Utility: Analyzing the Dual Nature of Plastic Packaging through Transport Packaging Cases

- The Core of the Circular Economy: Exploring the Possibility of Plastic Recycling from the Perspective of Transport Packaging

- Distinguishing between Genuine and False Green Promises: Verifying the Authenticity of Environmental Claims using Transport Packaging as an Example

- Technology and Environmental Protection: Identifying the Performance of Recycled Material Packaging through Transport Packaging Cases

Biography: Helps quality and product development professionals in the Toys and Hardgoods segments to develop and launch their products to various global markets. Upon taking on the role of Sustainability Product Manager in 2023, he continues to formulate business strategies, incorporating innovation and process improvement and pursuing quality excellence in supply-chain management.

Innovative Practices of SF in Cold Chain Packaging

Lu Peng, Head of SF Packaging R&D Innovation Laboratory, S.F.Express Co., Ltd.Presentation summary

Mainly introduce SF's innovative practices and exploration in cold chain packaging. Innovations in cold chain packaging solutions and research on cold chain standards. Overall planning the packaging innovation work of SF Group, building the company's green packaging system framework, and participating in the formulation of multiple industry standards

Distribution Environment Data Collection: China

Changfeng Ge, Professor, Rochester Institute of Technology (RIT)Presentation summary

This presentation reports the data collection and analyze regarding drops, shocks, and vehicle vibrations encountered during the distribution of Consumer Packaged Goods (CPGs) along representative routes in China.

Takeaways:

- Understand of how to collect the distribution data and provide analysis

- Understand vibration profles of different transport means

- Understand the drop/shock data during the distribution

Biography: Professor in Packaging Science at the Rochester Institute of Technology (RIT). He received his Doctor of Engineering degree in Mechanical Engineering from the University of Dortmund, Germany, and holds Master and Bachelor degree in Mechanical Engineering from Tongji University, China. Dr Ge joined RIT in 2005 and has served as the founding director of the APC Center for Packaging Innovation at RIT since 2008. Prior to joining RIT, Dr Ge worked as Senior Engineer in Singapore Institute of Industrial Research.

Diversified Packaging Technology Means Boost Efficiency and Reduce Costs for Transport Packaging

Tracy Yang, Deputy Director of Business Support Department, CPRIPresentation summary

As global supply chains become more intricate, the transportation and packaging industry confronts the dual challenge of cost reduction and efficiency enhancement. This presentation will examine the role of various packaging techniques in meeting these objectives through a series of case studies. The primary issues currently facing the transportation packaging industry are the reduction of cargo damage and cost reduction. The presentation will focus on these issues, sharing emblematic subcontracting cases. By applying diversified digital packaging technologies, it assists enterprises in precisely identifying the causes of problems and discovering solutions.

Takeaways:

- Reducing cargo damage: Common causes and solutions for cargo damage, with application case sharing;

- Cost reduction: Common cost reduction methods, with application case sharing;

- The application of diversified packaging technology: specific roles in packaging simulation, data collection, packaging design, packaging verification, and packaging standardization, demonstrated through case studies.

Biography: Graduated from Tianjin University of Science and Technology in 2015 with a Master's degree in Packaging. I have been working at CPRI until now, serving as a Senior R&D Engineer and Director of Business Support Department. We provide packaging consulting services such as cost reduction and efficiency improvement for industries such as new energy vehicles, home appliances, and healthcare through packaging simulation technology, logistics data collection, and packaging standard revision.

Study on the Current Status and Sustainable Development Trends of Circulating Packaging Box in China

Xin Guo, PhD Candidate, Tongji UniversityPresentation summary

The rapid development of China's express delivery industry has entered the "100 billion parcels" era as of 2021. Express packaging waste has become a major contributor to the increase in urban household garbage, leading to serious issues of resource wastage and environmental pollution. Promoting the green transition of express packaging based on circular economy principles—achieving cost reduction, efficiency improvement, and carbon reduction—has become the primary development direction. Several policy documents in China have also set quantitative goals for the development of circular packaging. However, the current circular packaging system needs improvement, consumer awareness of recycling is not yet established, the recycling mechanisms are not well developed, and there are gaps in relevant testing standards and environmental impact assessment methods. Therefore, this study, grounded in circular economy and value engineering concepts, aims to propose a design approach to achieve the optimal solution for "protection performance, environmental benefits, and economic benefits" of circular packaging in different scenarios (2B and 2C). Additionally, it will propose a method for accounting the environmental benefits of circular packaging that can be driven by policy.

Takeaways:

- The express packaging industry has entered the "100 billion parcels" era, with the circular packaging market projected to reach a scale of 200 to 300 billion. There is an urgent need for a circular packaging system solution that combines cost reduction, efficiency improvement, and carbon reduction.

- Currently, there is a mismatch between the strength performance requirements of circular packaging and the lifecycle of materials.

- Circular packaging exhibits a phenomenon of environmental burden shifting.

- Solving for the optimal solution of circular packaging in terms of "protection performance, environmental benefits, and economic benefits" can maximize overall benefits.

Biography: Xin Guo completed his Bachelor's and Master's degrees in Packaging Engineering and is currently pursuing further studies at Tongji University. His research focuses on circulating packaging box, exploring its policy implications, technological advancements, and business models. By examining the synergy between packaging functionality, economic benefits, and environmental impact, he aims to promote the sustainable development of express packaging in China. He has published five SCI papers and is a recipient of the WPO WorldStar Student Awards. Additionally, he is a co-author of China Products Carbon Footprint Factors Database.

Observation of Inter-governmental Negotiation Committee (INC) on Plastic Pollution and the Impact of Industry

Jason Ma, Deputy Lead/ Senior Regional Manager – Sustainability, Green Recycled Plastics Supply Chain Group/ Kmart GroupPresentation summary

Plastic pollution has become a global priority sustainable development issue along with global warming. Major economies and brands have also prioritized this topic in their respective policies and commitments. The Fourth Session of the Negotiations on an International Instrument to End Plastic Pollution (INC4) was held in Canada at the end of April this year. It focused on the design of plastic products and packaging, and the restricted use of materials and chemicals. It demonstrated the ambition of the United Nations Environment Programme to end plastic pollution. During the negotiation process, it also demonstrated the complexity of the supply chain and the challenges of implementation in reality. The supply chain of raw materials and packaging companies also made the industry's voice during the negotiations. How to actively respond to regulatory challenges and self-innovation is imperative. Bring inspiration to the industry through sharing of innovation, industrial policy responses and real supply chain cases.

Takeaways:

- The impact of the UN Environment Programme's plastic pollution negotiations on plastic packaging

- Challenges and opportunities in the industry chain in dealing with changes

- Supply chain and policy response case sharing

Biography: Mr. Ma is the expert on sustainability who has the experience across various industries, supporting circular economy on product innovation and supply chain delivery. Before joining Kmart, he used to be the technical manager of the world famous consulting company, and EU retailers on sustainability platform development and sustainable concept delivery, meanwhile as the deputy lead of Geen Plastic Recycling Group, and Sustainability consultant of PINFA (Halogen Free Flame Retardant Association) China. Mr. Ma holds the master degree in Chemical of New Jersey Institute of Technology and a bachelor degree in Fine chemistry of East China University of Science and Technology, PHD candidate of Donghua University in Advanced Material, Industry advisor of Jiao Tong University – China & UK Low Carbon School .

From Transportation Environment Data Collection to Test and Fragility Improvement: The Whole Process and the Application in Refrigerator Research

Ma Ning, Direction of Solid Mechanics Lab/Chief Reliability Engineer, Hefei Midea Refrigerator Co. Ltd.Presentation summary

With the trend of high capacity, thin cabinet for high valued refrigerator, the transportation process may have more impact on the refrigerator body. It will be more important for us to put more attention on the transportation environment, making the transportation environment factor map. Based on this, we can improve the test level and reliability for refrigerator products, make better package design and finally improve the whole product reliability.

Takeaways:

- The whole process for the data collection for the whole transportation process for refrigerator .

- The experiment research work based on the transportation environments data collection.

- The refrigerator fragility test and simulation method research and the following fragility improvement application.

Biography: After graduation from Seoul National University as a PhD in 2010, I joined Samsung Electronics as a senior research staff. From 2012, working as the reliability expert in Hyundai Group. Since 2019, I joined Midea Group in charge of mechanics reliability, package simulation, test and reliability improvement. Now, as the Direction of Solid Mechanics Lab, mainly take in charge of package simulation and improvement, solid mechanics improvement, multi-body kinematics and impact behavior research.

Innovative Method Used to Measure, Analyze and Report on Transport Vehicle Horizontal Acceleration Dynamicsn

Eric Joneson, VP Technology, Lansmont Corp.Presentation summary

Recording GPS information synchronized with contiguous DC triaxial acceleration data on a continuous basis for the duration of a trip has several advantages over the more common event driven data collection method. Using contiguous acceleration data, there is no possibility of missing a vehicle acceleration, braking, or turning activity, no matter how long the duration of the activity, or how low the acceleration level. The resulting data file can be analyzed post-trip in multiple ways to look for different types of data. GPS information shows when the vehicle speeds up, slows down, or turns. Since GPS and triaxial acceleration recording is synchronized, GPS data points to the acceleration data for these activities, all without an acceleration trigger level required. Through a more comprehensive analysis of those dynamics, laboratory test procedures can be developed to simulate the worst-of-normal characterizations of those dynamics.

Biography: Joneson holds a B.S. in Packaging from Michigan State University and has an extended experience in areas of transportation packaging, supply chain dynamics measurement and analysis and laboratory testing applications. He is a member of both the International Association of Packaging Research Institutes (IAPRI) and the International Safe Transit Association’s Global Board of Directors, as well as Lansmont’s Delegate of the ISTA Advocate Council. He participates and contributes within ASTM Committee D10 on Packaging. Joneson represents Lansmont as they support global research initiatives through various Packaging Research Institutes and Universities.

MIMO Vibration Test and Control of Large Specimens

Yao Jinyong, Associate Professor, Beihang UniversityPresentation summary

Multi-point excitation vibration test control technology is the key technology to carry out reliability and environmental tests on large and complex specimens. This paper reviews the control theory and technology of multi-point excitation random vibration. This paper analyzes and discusses the advanced control theory, technology and development trend at home and abroad in this field, focuses on the mutual coupling problem of the system and the design of the coupling controller for the multi-input multi-output vibration control system, compares the control effect of various feedback control schemes and the control performance of the typical multi-axis random vibration closed-loop control algorithm. This paper introduces a nonlinear power spectrum smoothing method that combines wavelet threshold theory with classical period graph estimation, improves the resolution of traditional estimation method without increasing the number of data samples, and significantly reduces the power spectrum jitter in the passband.

Takeaways:

- Test conditions and physical realizability judgment of multi-axis vibration

- Decoupling compensation control of multi-axis vibration

- Difficulties of multi-axis vibration control and improvement methods of control accuracy

Biography: He is currently an associate professor at the School of Reliability and Systems Engineering/Environment and Reliability Teaching and Research Center of Beihang University. Mainly engaged in product reliability engineering, product environment engineering, safety engineering system engineering, advanced test technology research, preresearch, aviation fund, Ministry of Science and Technology 04 major project, Ministry of Science and Technology Z018 special project, 973 national major project, COMAC large aircraft special project. Draft national standards such as GJB150.24A temperature - humidity - vibration - Height Test and Large specimen sand and Dust Test. Currently, he is a member of the Chinese Society of Systems Engineering and a member of TC122/SC2 of the Vibration Equipment sub-committee of the China Testing Machine Standardization Committee. He has published more than 40 SCI and EI papers in core journals and related conferences, obtained more than 20 patents, won one Science and Technology Progress Award of Machinery Industry Federation, one second prize and two third prizes of Science and Technology Progress Award of Ministry of Industry and Information Technology.

Discuss the Way to Change for Packaging enterprises in the Current Market Environment

Li Nan, Manager, Technology Innovation and Sustainability Development, IPS LandoPresentation summary

In recent years, with the advent of the post-COVID era, coupled with the impact of supply chain transfers and the weak global economic trend, the survival and development space of packaging companies has been greatly challenged. In addition, more and more packaging users have more personalized and higher requirements for product packaging. The previous extensive large-scale production business model and single-function packaging solutions are no longer suitable for the current new market environment. Therefore, how to change to open up a business model that adapts to the environment and the market and provide customers with forward-looking and sustainable solutions has become an urgent need.

Takeaways:

- Innovation and development of new environmentally friendly materials and packaging designs, as well as relevant supporting production equipment during "green"project

- Exploration of CO2 emission reduction in manufacturing, optimization of production processes, packaging structure design and applications.

- Examples of of challenges and solutions by packaging enterprises in the process of globalization.

- Proposal for collaboration by packaging company, brand user, organization and universities. Socially responsible actions for sustainable development and low carbon and plastics reduction.

Biography: Graduated from Shanghai Jiao Tong University, engaged in logistics and packaging for more than 25 years. Manager of the Innovation and Sustainability Development Department of Packaging Technology at IPS Lando now. Responsible for sustainable development of new materials and structures research and development and ESG related work. Has been worked as product packaging engineer at Siemens Mobile networks, global project manager and China team leader at Nokia Mobile networks. Participated in the development of relevant packaging testing standards and audit requirements for Nokia. And have supplier management, warehousing and logistics management related cooperation experience. Represented Nokia in a number of major customer level projects, such as participating in the rule-making and implementation of China Mobile's green packaging project. Judge of the first ISTA Design Competition.

Advancing ISTA's Vision Through Industry Collaboration and Research

Eric Hiser, Vice President, Standards & Certification, ISTAPresentation summary

ISTA is dedicated to realizing its vision of being the leading global resource for improving our world through transport packaging. In pursuit of this vision, ISTA has partnered with the industry to conduct groundbreaking research, which is then translated into new test protocols and enhancements to existing ones. This collaborative effort has also led to the creation of a world-class data repository, which ISTA and its members can utilize to model distribution more accurately on local, national, and international levels.

This presentation will provide updates on ISTA’s ongoing standards development projects, including a new ecommerce retailer fulfillment test. Additionally, updates will be given on ISTA’s data collection research project in China, as well as research conducted by the ISTA Advocate Research & Value Delivery Program and the ISTA Educational Foundation. Future research priorities will also be discussed.

Gain valuable insights into the new resources ISTA is developing, designed to help you and your company create effective packaging that minimizes product damage and optimizes resource usage.

Biography: Eric Hiser is Vice President of Standards & Certification at International Safe Transit Association (ISTA). He manages the ISTA Standards Council including all technical activities, development and maintenance of ISTA Procedures and Projects, and ISTA Certification programs for labs, packaged-products and people. Eric is a graduate of the Michigan State University School of Packaging with a Bachelor of Science Degree in Packaging. He has an extensive background in transport packaging performance testing as well as developing packaging for the Consumer Packaged Goods (CPG) market.

Rates, Registration & Payment 费率、注册和支付

Transportation & accommodations are not included in the following rates:

- Early-Bird Member Rate: 3000 CNY

- Regular Early-Bird Rate: 3800 CNY

- Regular Member Rate: 3600 CNY

- Regular Rate: 4000 CNY

- The participants successfully pay before August 1, 2024 can enjoy the early bird rate discount.

- The finalists of ISTA China Transport Packaging Design Competition are required to register in advance to participate in the award ceremony on September 5, 2024 at ISTA China Symposium for free.

- If you need to attend the entire agenda of ISTA China Symposium from September 5th to 6th, the symposium rate is CNY 800 per person.

PAYMENT INFORMATION

Account Name:上海顺且祥信息技术服务有限公司

Account Number:09032801040023874

Opening Bank:中国农业银行股份有限公司上海紫竹科学园区支行

The symposium recommends using electronic transfer payment before August 25th. After the payment is received, it is expected to issue a value-added tax electronic special invoice within 3 working days. Funds received after August 25th are expected to receive value-added tax electronic special invoices within one week after the end of the symposium. Cash payment services are not provided on-site, and attending representatives can make payments through WeChat scanning and other methods.

REGISTRATION START & END

Registration will start on June 15, 2024 and end on September 1, 2024.

CONTACTS

Andy Huang: andy@packagetest.net

Helena Zhu: dzhu@cca-im.com

Events 活动

2024 5th ISTA China Transport Packaging Design Competition Finals

- Time:2024/09/04 9:00-17:00

- Place:M49 Meeting Room, N5 Hall, Shanghai New International Expo Center,No.2345 Longyang Road, Pudong New Area, Shanghai (021)28906666

- The judges, contestants, and participants of the organizing committee of the competition will register for free participation tickets to the Interfoam China 2024 exhibition and various forums on September 4, 2024.

Seminar “Logistics Supply Chain Cost Reduction and Recycling of Foam Materials for Packaging”

- Time:2024/09/04 13:30-17:00

- Place:M50 Meeting Room, N5 Hall, Shanghai New International Expo Center,No.2345 Longyang Road, Pudong New Area, Shanghai (021)28906666

- The speakers, guests, hosts, and other organizers of this forum will register for free participation tickets to the Interfoam China 2024 exhibition and various forums from September 3-5, 2024.

Interfoam China 2024 Shanghai International Foam Material Technology Industry Exhibition

- Time:2024/09/03-2024/09/05

- Place:Shanghai New International Expo Center,No.2345 Longyang Road, Pudong New Area, Shanghai

- Exhibition Official Website:www.interfoam.cn

Sponsorship Opportunities 赞助机会

Diamond Sponsors

Sponsorship rate: 40,000 CNY

Benefits include the following:

- As a "Diamond Sponsor", the company name and/or company logo will be displayed on the backboard at main venue (submission deadline August 15, 2024;

- 5 complimentary symposium attendee registrations; (including two lunches and one dinner);

- Corporate promotional videos will be shown during the tea breaks;

- A complimentary exhibition booth;

- 2 pages for promotion on the internal page of the electronic Symposium magazine (submission deadline August 15, 2024;

- Company name and/or logo will be included on the 2024 ISTA China Packaging Symposium website and official WeChat account;

- Priority opportunities to engage with attendees.

- Deadline for submission of all materials: August 15, 2024

Platinum Sponsors

Sponsorship rate: 30,000 CNY

Benefits include the following:

- As a "Platinum Sponsor", the company name and/or company logo will be displayed on the backboard at main venue (submission deadline August 15, 2024;

- 3 complimentary symposium attendee registrations; (including two lunches and one dinner);

- A complimentary exhibition booth;

- 2 pages in conference materials for recognition;

- 2 pages for promotion on the internal page of the electronic Symposium magazine (submission deadline August 15, 2024;

- Company name and/or logo will be included on the 2024 ISTA China Packaging Symposium website and official WeChat account;

- One ISTA souvenior;

- Priority opportunities to engage with attendees.

- Deadline for submission of all materials: August 15, 2024

Gold Sponsors

Sponsorship rate: 20,000 CNY

Benefits include the following:

- As a "Gold Sponsor", the company name or LOGO will be reflected on the backboard of the main venue (submission deadline August 15, 2024;

- 2 complimentary symposium attendee registrations; (including two lunches and one dinner);

- A complimentary exhibition booth;

- 2 pages in conference materials for recognition;

- 2 pages for promotion on the internal page of the electronic Symposium magazine (submission deadline August 15, 2024;

- Company name and/or logo will be included on the 2024 ISTA China Packaging Symposium website and official WeChat account;

- One ISTA souvenior;

- Priority opportunities to engage with attendees.

- Deadline for submission of all materials: August 15, 2024

Remittance Information:

- Contact: Helena Zhu

- Tel: 021-34293970

- Email: dzhu@cca-im.com

Sponsorship Contact:

- Contact: Andy Huang

- Tel: 13141368660 (same as WeChat account)

- Email: andy@packagetest.net

- Website: www.ista-china.net

Exhibition Opportunities 展览机会

Exhibition Time:

- September 5, 2024-September 6, 2024

- Registration Deadline: August 15, 2024

Booth Fee: CNY 6000/booth

Exhibitor Benefits:

- 1 exhibition assistant who will have a complimentary Symposium registration (including two lunches and one dinner)

- The name or LOGO of exhibitors shall be displayed in the information material of 2024 ISTA China Packaging Symposium.

- The official website of ISTA and official website of ISTA China will display the exhibitors' names or logos.

- Exhibitor name and logo on the WeChat official account.

- The organizer will invite important guests to tour the exhibition booths.

- Priority opportunites to engage with attendees.

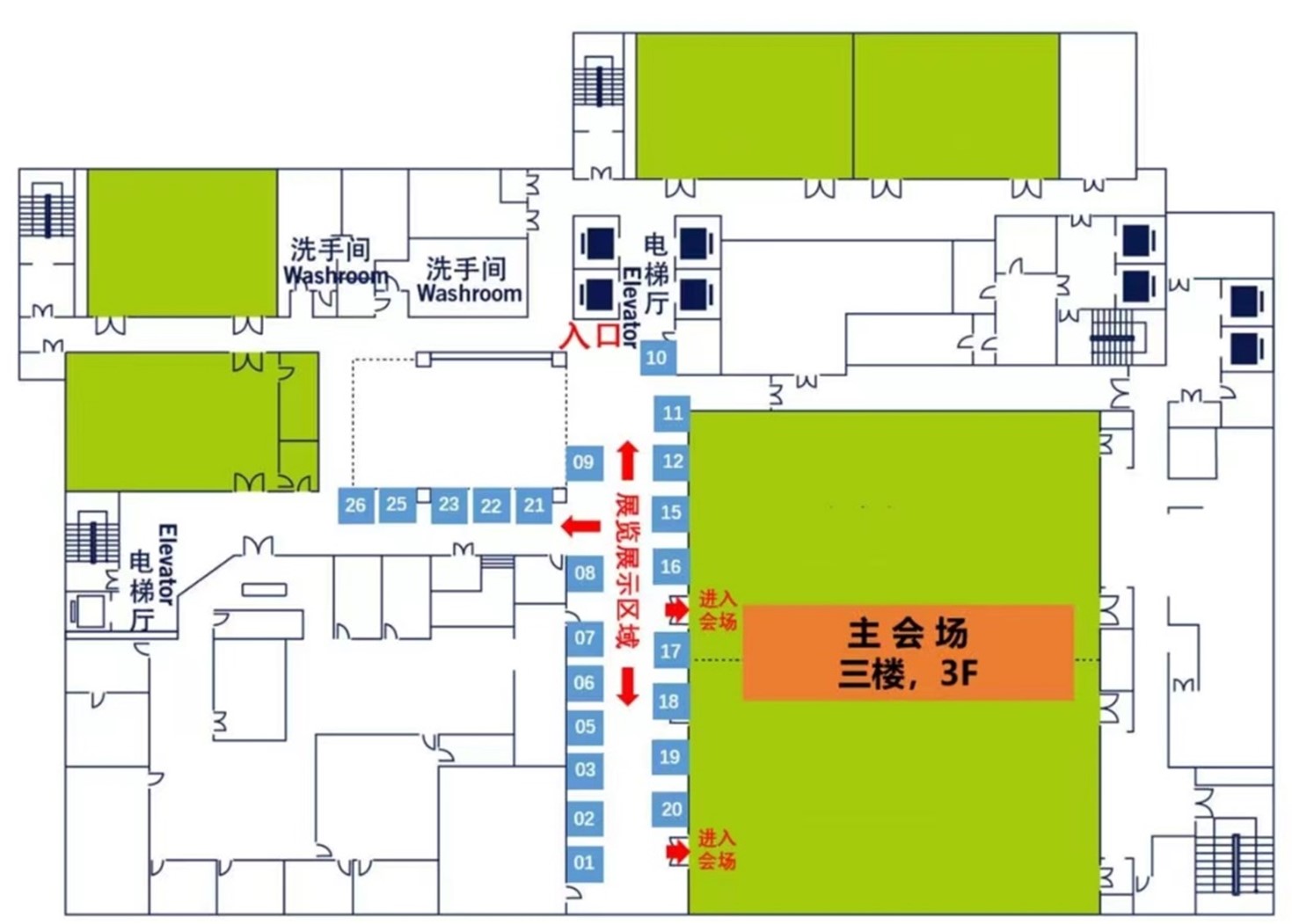

Booth parameters:

- Booth size: 2m * 2.4m;

- Booth supporting equipment: table (1.8m), 2 chairs;

Booth Set-Up: Evening of September 4, 2024

Booth Tear-Down: Evening of September 6, 2024

Booth Photo and Sketch Map: To come

Remittance Information:

Account Name: 上海顺且祥信息技术服务有限公司

Account Number: 09032801040023874

Opening Bank: 中国农业银行股份有限公司上海紫竹科学园区支行

Invoice Subject: Service fee

Contact: Helena Zhu

- Tel: 021-34293970

- Email: dzhu@cca-im.com

Exhibition Contact:

- Contact: Andy Huang

- Tel: 13141368660 (same as WeChat account)

- Email: andy@packagetest.net

- Website: www.ista-china.net

Hotel & Transportation

酒店和旅行

HOTEL

We are pleased to provide ISTA China Packaging Symposium attendees a special hotel rate at the Wyndam Shanghai Nanxiang Hotel.

Wyndham Shanghai Nanxiang

No. 789 Chaxi Road, Jiading District, Shanghai

Booking Contact:

Ms. Li: 17317236820 (same as WeChat account). Please mark ISTA China Packaging Symposium.

Rate:

Double Room/Twin Room: CNY 450/night

TRANSPORTATION MODE

Inter provincial transportation:

- High speed rail: It is recommended to go to Shanghai Station, Shanghai West Station, or Shanghai Hongqiao Station

- Air: It is recommended to go to Shanghai Hongqiao International Airport

- Urban transportation:

- Metro: Take Shanghai Metro to Nanxiang Station on Line 11 and walk 1 kilometer to reach the hotel

Speaker Benefits & Reminders 演讲者福利和提醒

KEY BENEFITS AND IMPORTANT REMINDERS:- Free participation fees and participate in the symposium agenda from September 5-6, 2024;

- Free registration for the Interfoam China 2024 exhibition and “Logistics Supply Chain Cost Reduction and Recycling of Foam Materials for Packaging” Forum on September 4, 2024, as well as participation tickets to other forums (Shanghai New International Expo Center, No. 2345 Longyang Road,, Pudong New Area, Shanghai);

- Free on-site watch of 2024 ISTA China 5th Transport Packaging Design Competition Finals on September 4, 2024 (Shanghai New International Expo Center, M49 Meeting Room, N5 Hall , 9:00-17:00);

- Promote and introduce globally with the help of ISTA China official account, website and ISTA official website;

- Front row guest seats at ISTA China Symposium, where the organizer provides promotional introductions to the guests and their respective companies;

- Other representatives of the organization where the guest is from can receive discounted participation fees.

- The symposium will be held from September 5-6, 2024. Each speaker will give a speech for 30 minutes (including 5 minutes of on-site Q&A). The presentation can be in Chinese or English, with a PPT format screen ratio of 16:9 and a display screen resolution of 2560 * 1024.

- Please register and provide personal information through the channels provided by the organizer before July 30, 2024.

- The theme agenda of the symposium will be notified to the speakers in advance, and other relevant contents of the symposium will be published and updated on ISTA China website: www.ista-china.org (the website is being migrated) and ISTA China official account: ISTA Information Service.

- The guest speaker is responsible for their own travel and hotel expenses.

- Contact person of the organizer, Louise Lu, louis@packagetest.net